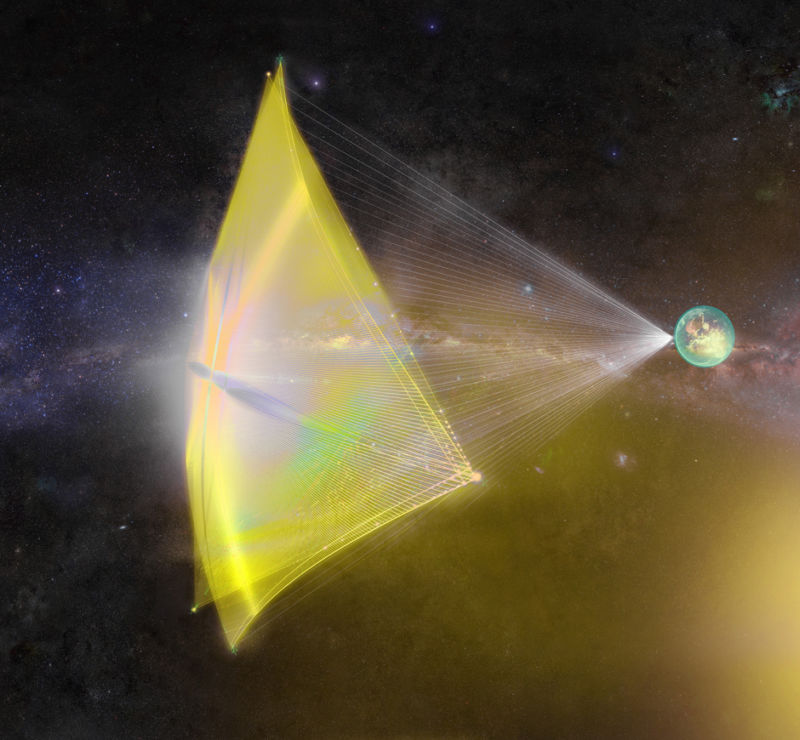

The material science of building a light sail to

take us to Alpha Centauri

We're unsure about the best

material and don't have the measurements to know.

It has been about two years since

Yuri Milner announced his most audacious piece of science-focused philanthropy:

Breakthrough Starshot, an attempt to send hardware to Alpha Centauri by

mid-century. Although the technology involved is a reasonable extrapolation of

things we already know how to make, being able to create materials and

technology that create that extrapolation is a serious challenge. So much of

Breakthrough Starshot's early funding has gone to figuring out what

improvements on current technology are needed.

Perhaps the least well-understood

developments we need come in the form of the light sail that will be needed to

accelerate the starshots to 20 percent of the speed of light. We've only put

two examples of light-driven sails into space, and they aren't anything close

to what is necessary for Breakthrough Starshot. So, in this week's edition of

Nature Materials, a team of Caltech scientists looks at what we'd need to do to

go from those examples to something capable of interstellar travel.

The size of the problem

One of our best examples of a

light sail was put into space on the IKAROS craft, which was capable of

accelerating up to speeds of 400 meters/second. Breakthrough Starshot's craft

are expected to travel in the area of 60,000 kilometers/second and accelerate

to that speed before leaving the Solar System. So the amount we can learn from

the existing craft is fairly limited.

Those speeds—and the acceleration

needed to get there—provide a rough idea of the size of the sail we'd need, and

the dimensions are pretty impressive: 10 square meters but weighing less than a

gram. That, the Caltech researchers calculate, means that the sail will have to

average out to being 100 atoms thick yet still be able to transmit the force of

acceleration. Graphene is one of the strongest materials we're aware of, so it

might work for Breakthrough, but it's also transparent at some wavelengths and

absorbs at many others, so it can only act as structural support.

There is some good news in that

100-atom-thick figure. The sail will run into a variety of energetic particles

in the interplanetary and interstellar medium, but most of these will be

hydrogen and helium. And, based on how deeply those particles penetrate into

other materials, there's a good chance that the hydrogen and helium will pass

straight through the solar sail. Dust particles create more of a problem, but

the authors estimate that they would obliterate about 0.1 percent of the total

sail area, and most of that would occur after the acceleration has been

completed.

So what we're left with is

primarily the challenge of building the material that will reflect light from

the solar sail. Or, as we'll see, the collection of interlocking challenges.

Sailing

Light sails work because photons

carry momentum, and they'll impart a bit of that to reflective surfaces as they

bounce off. Starshot proposes to sync up a large collection of lasers on Earth

and focus this on the light sail in order to accelerate it rapidly. That means

the lasers will have to be at a wavelength that can pass through the atmosphere

without being absorbed or scattered; the authors suggest that the near-infrared

(with a one- or two-micrometer wavelength) would be a good choice.

So the sail surface would have to

reflect in those wavelengths. Gold and silver, among other metals, are already

known to do so and can be made in thin films. Problem solved, right?

Not exactly. As the authors note,

managing light isn't just a matter of tackling the problem of reflecting light;

it's a series of interlinked problems. Even if we could make thin films of

these metals a few atoms thick on a sail, the relatively high weight per-atom

means that we could easily blow past the sail's weight limit. And, even more

problematic, while these metals reflect most of the light in these wavelengths,

a lot of what doesn't get reflected is absorbed. At the intensity of the lasers

involved in accelerating the craft, the heat from those absorbed photons would

quickly destroy the sail.

Instead, the authors look into

partly reflective materials that have a high refractive index and low

absorption. The high refraction allows for the possibility of making

light-manipulating structures on the surface of the sail that contribute to its

reflectivity. The researchers consider a handful of semiconducting materials

that fit the bill, rejecting a number of them because their component atoms

weigh too much (like tin). The reflection/refraction of these materials also

have to cover a broad range of wavelengths since, once the craft is moving fast

enough, the incoming photons will be red-shifted.

In the end, nothing meets the

researchers' full list of desires. So they settled for two out of three and

focus on silicon, diamond, and molybdenum disulfide.

There are other issues, however.

These materials also have to efficiently radiate away any heat they do wind up

with—technically, they have to have a high emissivity. This will obviously

cause problems with, as the researchers put it, "melting or other thermal

failure modes." But it can cause problems even below that. As silicon

heats up, the amount of light it absorbs will increase, creating the prospect

of a thermal runaway.

Right now, the team suggests that

we don't even have good measurements of some of the material properties that

we'd need to fully evaluate some of these details. We've got measurements of

bulk material, but not thin films. So there's an entire research field that has

to be advanced for us to fully understand the tradeoffs we face.

Structure

While materials like silicon

won't reflect much of the light, they have a high refractive index, which means

they will bend a lot of it. If you structure the surfaces of these materials on

scales similar to the wavelength of the incoming light, they can potentially

bend it in a way that is functionally equivalent to reflecting it. So, the

researchers also considered a variety of designs for the surface.

And here they found yet another

trade-off. While the best light reflection (nearly perfect reflection) came

with a multi-layered, 3D structure, that added significantly to the weight. By

contrast, they weren't able to reflect as much light using a pattern of holes

drilled into the silicon, but this significantly lowered the weight. When they

compared the acceleration of the two options, they were able to get a

noticeably larger acceleration from the less-efficient solution purely due to

the weight.

Adding to the challenges they

face, the sail itself won't be a simple flat sheet. That's because even the

slightest imperfections on the surface or tilt of a sheet could send it off in

unexpected directions during acceleration. Instead, current thinking focuses on

a spherical sail and a donut-shaped light field, which could self-correct for

small perturbations in the sail. That design, however, probably isn't conducive

to making the sail from single sheets of material (assuming we could figure out

how to grow them at scales of 10 square meters). So we're going to have to bond

many individual panels of these materials together, something that we don't

currently know how to do.

Overall, the paper does a good

job of laying out what we'd need to know to start choosing materials for a

Breakthrough light sail. But it also highlights that this isn't a matter of

finding the one perfect solution; instead, it's about managing multiple,

sometimes conflicting priorities and engineering a solution that partially

satisfies all of them. "We argue that a successful design of the light

sail will require synergetic engineering," the authors conclude,

"simultaneous optimization and consideration of all of the parameters

described above."

Reference: https://bit.ly/2TWoUEM

No comments:

Post a Comment